KURITA’s water treatment chemicals, plants and maintenance service help you saving costs by extending equipment lifetime, increasing production, saving energy and product quality.

Boiler water treatment chemicals

Kurita boiler water treatment chemicals are used to prevent trouble in boilers and help them operate efficiently.

We offer chemicals that meet high safety standards in terms of ingredients as well as chemical effects.

Food Grade Chemicals

- Boiler component for scale and corrosion inhibitor

- Oxygen Scavenger

- Corrosion inhibitor for steam and condensate line

- Multi functional chemical

General Used Chemicals

- Boiler compound for scale and corrosion inhibitor

- Several types of oxygen scavenger

- Sludge dispersant

- Multifunctional boiler compound

Other Chemicals

- On stream hardness scale remover

- Used for substitute soda boiling or after boiler maintenance work

- Corrosion inhibitor for idle boiler.

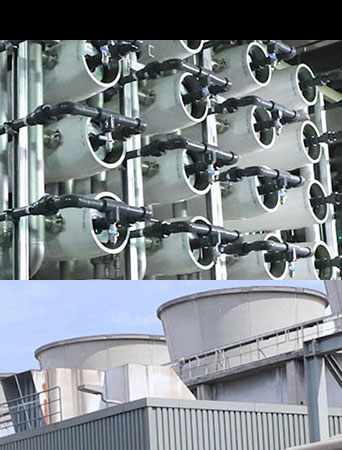

Cooling water treatment chemicals

We offer cooling water treatment chemicals that prevent trouble caused by water as well as propagating of Legionella bacteria and improve the system operation efficiency in the cooling systems of factories and office buildings to help reduce their energy usage.

Open Recirculating Cooling Water System

- Corrosion & scale inhibitor for high alkaline and hardness

- Corrosion & scale inhibitor for low hardness or high salinity

- Scale inhibitor for high heat flux cooling water system

- Biocide

- Slime control chemical

- Corrosion inhibitor for initial treatment

- Sludge dispersant

- Multifunctional chemical for small-medium size cooling water system

Closed Recirculating Cooling Water Systm

- Corrosion inhibitor

- Biocide

- Sludge dispersant

Other Chemicals

- On stream scales remover

Waste water treatment chemicals

We offer wastewater treatment chemicals that help reduce environmental impact through proper wastewater treatment by removing suspended solids in industrial wastewater of various characteristics and dehydrating and deodorizing sludge.

- Flocculant

- Organic coagulant

- Dehydrant

- Heavy metal scavenger

- Odor control chemical

RO membrane water treatment chemicals

There are five problems associated with RO membranes: clogging, the deterioration of the permeable water quality, the decrease of water for treatment, the increased cost for membrane change, and the large amount of water used and wastewater generated. Kurita offers the solution to these problems

- Pretreatment chemicals

- Anti-scalant for membrane surface

- Slime control agent

- Cleaning agent

Automobile paint booth chemicals

Wet painting booths are used extensively in the painting of automobiles and auto parts. Aqueous paint, the most widely used form of paint in this process, contains a large amount of surfactants that may cause many different problems, such as environmental abnormalities and an increase in waste resulting from the formation of foam and poor coagulation. With proven track record over many years and wealth of experience in water treatment, Kurita developed a painting booth treatment agent that has a high foam-inhibition capacity, even for aqueous paint, and also exhibits a high coagulative

- Paint killer for solvent paint

- Paint killer for waterborne paint

- Anionic and cationic polymer flocculant

Pulp and paper mills chemicals

- Retention aid, recovery for water in paper mills

- Deposit control agents for scale

- Deposit control agents for slime

- Antifoaming agent

- Microbiological control agent

- Felt conditioning agent